A cikin tsarin samar da sinadarai, matsa lamba ba wai kawai yana rinjayar ma'auni na ma'auni da ƙimar amsawar tsarin samarwa ba, amma har ma yana rinjayar mahimman sigogi na tsarin ma'auni na kayan aiki.A cikin tsarin samar da masana'antu, wasu suna buƙatar matsa lamba mai yawa fiye da matsa lamba na yanayi, irin su babban matsin lamba polyethylene.Polymerization ana gudanar da shi a babban matsin lamba na 150MPA, kuma wasu suna buƙatar aiwatar da su a matsa lamba mara kyau fiye da na yanayi.Irin su injin distillation a matatun mai.Babban matsin tururi na masana'antar sinadarai ta PTA shine 8.0MPA, kuma matsin ciyarwar iskar oxygen shine kusan 9.0MPAG.Ma'aunin matsi yana da yawa sosai, ya kamata ma'aikaci ya bi ƙa'idodin amfani da kayan auna matsi daban-daban, ƙarfafa kulawar yau da kullun, da duk wani sakaci ko rashin kulawa.Dukkanin su na iya haifar da babbar lalacewa da asara, kasa cimma burin babban inganci, yawan amfanin ƙasa, ƙarancin amfani da samar da lafiya.

Sashe na farko ainihin manufar ma'aunin matsi

- Ma'anar damuwa

A cikin samar da masana'antu, wanda aka fi sani da matsa lamba yana nufin ƙarfin da ke aiki daidai da kuma a tsaye a kan yanki na yanki, kuma girmansa yana ƙayyade wurin da ke da karfi da kuma girman ƙarfin tsaye.An bayyana ta hanyar lissafi kamar:

P=F/S inda P shine matsi, F shine ƙarfin tsaye kuma S shine yanki mai ƙarfi

- Naúrar matsa lamba

A cikin fasahar injiniyanci, ƙasata ta ɗauki Tsarin Raka'a ta Duniya (SI).Nau'in lissafin matsa lamba shine Pa (Pa), 1Pa shine matsi da ƙarfin 1 Newton (N) ke haifar da shi a tsaye kuma daidai da yanki na 1 murabba'in mita (M2), wanda aka bayyana a matsayin N/m2 (Newton/) murabba'in mita), Baya ga Pa, ma'aunin matsa lamba na iya zama kilopascals da megapascals.Alakar musanya tsakanin su ita ce: 1MPA=103KPA=106PA

Saboda yawan al'ada na shekaru da yawa, har yanzu ana amfani da matsin yanayi na injiniya a aikin injiniya.Domin sauƙaƙe jujjuyawar juna cikin amfani, an jera alaƙar musanya tsakanin raka'o'in ma'aunin matsi da aka saba amfani da su a cikin 2-1.

| Naúrar matsa lamba | Yanayin injiniya kg/cm2 | mmHg | mmH2O | atm | Pa | mashaya | 1b/in2 |

| Kgf/cm2 | 1 | 0.73×103 | 104 | 0.9678 | 0.99×105 | 0.99×105 | 14.22 |

| mmHg | 1.36×10-3 | 1 | 13.6 | 1.32×102 | 1.33×102 | 1.33×10-3 | 1.93×10-2 |

| mmH2o | 10-4 | 0.74×10-2 | 1 | 0.96×10-4 | 0.98×10 | 0.93×10-4 | 1.42×10-3 |

| Atm | 1.03 | 760 | 1.03×104 | 1 | 1.01×105 | 1.01 | 14.69 |

| Pa | 1.02×10-5 | 0.75×10-2 | 1.02×10-2 | 0.98×10-5 | 1 | 1 × 10-5 | 1.45×10-4 |

| Bar | 1.019 | 0.75 | 1.02×104 | 0.98 | 1 × 105 | 1 | 14.50 |

| Ib/in2 | 0.70×10-2 | 51.72 | 0.70×103 | 0.68×10-2 | 0.68×104 | 0.68×10-2 | 1 |

- Hanyoyin bayyana damuwa

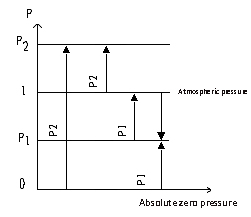

Akwai hanyoyi guda uku don bayyana matsa lamba: cikakken matsa lamba, matsa lamba, matsi mara kyau ko mara kyau.

Matsin da ke ƙarƙashin cikakken vacuum ana kiransa cikakken matsa lamba na sifili, kuma matsa lamba da aka bayyana akan cikakken matsi na sifili ana kiransa cikakken matsa lamba.

Matsin ma'auni shine matsi da aka bayyana akan matsi na yanayi, don haka yanayi ne daidai (0.01Mp) nesa da cikakken matsi.

Wato: P tebur = P cikakken-P babba (2-2)

Ana kiran matsa lamba mara kyau sau da yawa vacuum.

Ana iya gani daga ma'auni (2-2) cewa matsa lamba mara kyau shine ma'aunin ma'auni lokacin da cikakken matsa lamba ya kasance ƙasa da matsa lamba na yanayi.

Dangantakar da ke tsakanin cikakken matsa lamba, matsa lamba, matsa lamba mara kyau ko vacuum ana nunawa a cikin hoton da ke ƙasa:

Yawancin ma'aunin matsi da ake amfani da su a masana'antu su ne ma'aunin ma'auni, wato, alamar ƙimar ma'aunin matsa lamba shine bambanci tsakanin cikakken matsa lamba da matsa lamba na yanayi, don haka matsi cikakke shine jimlar ma'auni da matsa lamba na yanayi.

Sashi na 2 Rarrabe Kayan Aunar Matsi

Matsakaicin adadin da za a auna a cikin samar da sinadarai yana da faɗi sosai, kuma kowanne yana da nasa musamman a ƙarƙashin yanayin tsari daban-daban.Wannan yana buƙatar amfani da kayan auna matsi tare da tsari daban-daban da ka'idodin aiki daban-daban don saduwa da buƙatun samarwa daban-daban.Bukatu daban-daban.

Dangane da ka'idodin juzu'i daban-daban, kayan aikin auna matsi za a iya kasu kusan kashi huɗu: ma'aunin ma'aunin ma'aunin ruwa;ma'aunin matsa lamba na roba;ma'aunin matsa lamba na lantarki;piston matsa lamba ma'auni.

- Ma'aunin ma'aunin ma'aunin ruwa

Ka'idar aiki na ma'aunin ma'aunin ma'aunin ruwa yana dogara ne akan ka'idar hydrostatics.Na'urar ma'aunin ma'auni da aka yi bisa ga wannan ka'ida yana da tsari mai sauƙi, ya dace don amfani, yana da daidaitattun ma'auni mai mahimmanci, yana da arha, kuma yana iya auna ƙananan matsi, don haka ana amfani dashi sosai a cikin samarwa.

Za'a iya raba ma'aunin matsi na ginshiƙan ruwa zuwa ma'aunin matsa lamba U-tube, ma'aunin matsi guda ɗaya, da ma'aunin ma'aunin bugun bututu bisa ga tsarinsu daban-daban.

- Na'urar matsa lamba na roba

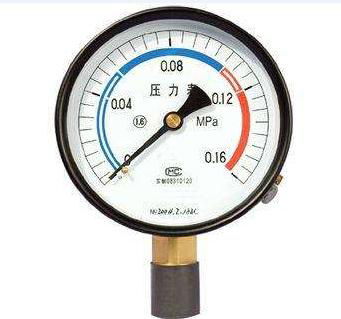

Ana amfani da ma'aunin ma'auni mai mahimmanci a cikin samar da sinadarai saboda yana da fa'idodi masu zuwa, kamar tsari mai sauƙi.Yana da ƙarfi kuma abin dogara.Yana da kewayon ma'auni mai faɗi, mai sauƙin amfani, mai sauƙin karantawa, ƙarancin farashi, kuma yana da isasshen daidaito, kuma yana da sauƙin yin aikawa da umarnin nesa, rikodin atomatik, da sauransu.

Ana yin ma'aunin ma'aunin roba na roba daban-daban na siffofi daban-daban don samar da nakasassu na roba a ƙarƙashin matsin lambar.A cikin ƙayyadaddun ƙididdiga, fitarwar fitarwa na nau'in roba yana cikin alaƙar layi tare da matsa lamba don aunawa., Don haka sikelin sa uniform, na roba sassa daban-daban, matsa lamba kewayon shi ma daban-daban, kamar corrugated diaphragm da bellows aka gyara, kullum amfani da low matsa lamba da kuma low matsa lamba lokatai, guda nada spring tube (gayyace a matsayin spring tube) da kuma mahara. Ana amfani da bututun bazara don babban matsi, matsakaita ko auna injin.Daga cikin su, bututun bazara mai coil guda ɗaya yana da matsakaicin matsakaicin matsakaicin ma'aunin matsi, don haka shine mafi yawan amfani da shi wajen samar da sinadarai.

- Masu watsa matsi

A halin yanzu, ana amfani da na'urori masu watsa wutar lantarki da na huhu a masana'antar sinadarai.Kayan aiki ne wanda ke ci gaba da auna ma'aunin da aka auna kuma ya canza shi zuwa sigina na yau da kullun (matsin iska da na yanzu).Ana iya watsa su ta nisa mai nisa, kuma ana iya nuna matsa lamba, yin rikodin ko daidaitawa a cikin ɗakin kulawa na tsakiya.Ana iya raba su zuwa ƙananan matsa lamba, matsakaicin matsa lamba, babban matsa lamba da cikakken matsa lamba bisa ga ma'auni daban-daban.

Sashi na 3 Gabatarwa ga Kayan aikin Matsi a Tsiren Sinadarai

A cikin tsire-tsire masu sinadarai, ana amfani da ma'aunin ma'aunin bututun Bourdon gabaɗaya don ma'aunin matsi.Koyaya, ana amfani da diaphragm, diaphragm corrugated da ma'aunin matsi na karkace bisa ga buƙatun aiki da buƙatun kayan aiki.

Matsakaicin ma'aunin ma'aunin ma'aunin ma'aunin wurin shine 100mm, kuma kayan bakin karfe ne.Ya dace da duk yanayin yanayi.Ma'aunin matsa lamba tare da haɗin gwiwar mazugi mai kyau na 1 / 2HNPT, gilashin aminci da membrane mai iska, nunin kan-site da sarrafawa shine pneumatic.Daidaiton sa shine ± 0.5% na cikakken sikelin.

Ana amfani da mai isar da wutar lantarki don watsa siginar nesa.An siffanta shi da babban daidaito, kyakkyawan aiki, da babban abin dogaro.Daidaiton sa shine ± 0.25% na cikakken sikelin.

Ƙararrawa ko tsarin kullewa yana amfani da matsi.

Sashe na 4 Shigarwa, Amfani da Kula da Ma'aunin Matsi

Daidaiton ma'aunin matsa lamba ba wai kawai yana da alaƙa da daidaiton ma'aunin ma'aunin da kansa ba, har ma da ko an shigar da shi daidai, ko daidai ko a'a, da yadda ake amfani da shi da kiyaye shi.

- Shigar da ma'aunin matsa lamba

Lokacin shigar da ma'aunin matsa lamba, ya kamata a ba da hankali ga ko hanyar da aka zaɓa da kuma wurin da aka zaɓa ya dace, wanda ke da tasiri kai tsaye ga rayuwar sabis ɗinsa, daidaiton ma'auni da ingancin kulawa.

Abubuwan da ake buƙata don ma'aunin ma'auni, ban da daidai zaɓin takamaiman wurin ma'aunin matsa lamba akan kayan aikin samarwa, yayin shigarwa, ƙarshen ƙarshen ƙarshen bututun da aka saka a cikin kayan aikin ya kamata a kiyaye shi tare da bangon ciki na ma'aunin haɗin gwiwa. na kayan aikin samarwa.Kada a sami fitowa ko bursu don tabbatar da cewa an sami matsi na tsaye daidai.

Wurin shigarwa yana da sauƙin lura, kuma kuyi ƙoƙari don guje wa tasirin girgiza da zafin jiki mai girma.

Lokacin auna matsi na tururi, ya kamata a shigar da bututu na condensate don hana hulɗar kai tsaye tsakanin tururi mai zafi da abubuwan da aka gyara, kuma bututu ya kamata a rufe a lokaci guda.Don kafofin watsa labaru masu lalata, ya kamata a shigar da tankunan keɓe da ke cike da kafofin watsa labarai na tsaka tsaki.A takaice, bisa ga daban-daban kaddarorin na auna matsakaici (high zazzabi, low zazzabi, lalata, datti, crystallization, hazo, danko, da dai sauransu), dauki m anti-lalata, anti-daskarewa, anti-tarewa matakan.Hakanan ya kamata a sanya bawul ɗin kashewa tsakanin tashar mai ɗaukar matsi da ma'aunin matsa lamba, ta yadda lokacin da aka cika ma'aunin matsa lamba, yakamata a shigar da bawul ɗin kashe kusa da tashar mai ɗaukar nauyi.

A cikin yanayin tabbatarwa a wurin da kuma yawan zubar da bututun motsa jiki, bawul ɗin kashewa na iya zama maɓalli ta hanyoyi uku.

Katheter mai jagorantar matsa lamba bai kamata ya yi tsayi da yawa ba don rage jinkirin alamar matsa lamba.

- Amfani da kiyaye ma'aunin matsa lamba

A cikin samar da sinadarai, ma'aunin matsa lamba sau da yawa yana shafar matsakaicin ma'auni kamar lalata, ƙarfi, crystallization, danko, ƙura, matsanancin matsin lamba, zazzabi mai zafi, da sauye-sauye masu kaifi, wanda galibi yakan haifar da gazawa daban-daban na ma'aunin.Don tabbatar da aikin yau da kullun na kayan aiki, rage abin da ya faru na gazawa, da kuma tsawaita rayuwar sabis, ya zama dole a yi aiki mai kyau na kulawa da kulawa da kulawa na yau da kullun kafin fara samarwa.

1. Kulawa da dubawa kafin fara samarwa:

Kafin fara samarwa, ana yin aikin gwajin matsa lamba akan kayan aiki, bututun bututu, da dai sauransu. Matsalolin gwajin gabaɗaya kusan sau 1.5 na matsa lamba na aiki.Ya kamata a rufe bawul ɗin da aka haɗa da kayan aiki yayin gwajin matsa lamba.Buɗe bawul ɗin akan na'urar ɗaukar matsi kuma duba ko akwai wani ɗigogi a cikin gidajen abinci da walda.Idan an sami wani yatsa, ya kamata a kawar da shi cikin lokaci.

Bayan an gama gwajin matsa lamba.Kafin shirya don fara samarwa, duba ko ƙayyadaddun ƙayyadaddun bayanai da samfurin ma'aunin matsa lamba da aka shigar sun dace da matsa lamba na matsakaicin matsakaici da ake buƙata ta hanyar;ko ma'aunin calibrated yana da takaddun shaida, kuma idan akwai kurakurai, yakamata a gyara su cikin lokaci.Ana buƙatar cika ma'aunin ma'aunin ruwa da ruwan aiki, kuma dole ne a gyara ma'aunin sifili.Ma'aunin matsa lamba sanye take da na'urar keɓewa yana buƙatar ƙara ruwa mai keɓewa.

2. Kulawa da duba ma'aunin matsi lokacin tuƙi:

A lokacin farawa na samarwa, ma'auni na ma'auni na matsa lamba, don kauce wa lalacewa ga ma'auni na matsa lamba saboda tasirin nan take da kuma wuce haddi, ya kamata a bude bawul a hankali kuma ya kamata a lura da yanayin aiki.

Don ma'aunin ma'aunin ma'aunin tururi ko ruwan zafi, ya kamata a cika na'urar da ruwan sanyi kafin buɗe bawul akan ma'aunin matsa lamba.Lokacin da aka sami ɗigon ruwa a cikin kayan aiki ko bututun, ya kamata a yanke bawul ɗin da ke kan na'urar ɗaukar matsi cikin lokaci, sannan a yi maganinta.

3. Kula da ma'aunin matsi na yau da kullun:

Ya kamata a duba kayan aikin da ke aiki akai-akai kowace rana don kiyaye tsaftar mita da kuma duba amincin mitar.Idan an gano matsalar, kawar da ita cikin lokaci.

Lokacin aikawa: Dec-15-2021